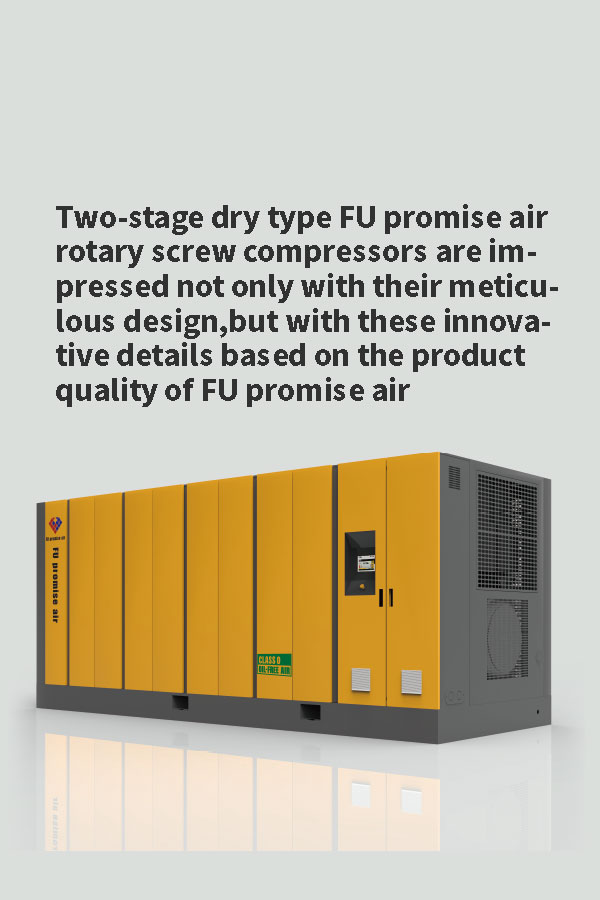

Product Features

High Efficiency and Energy Saving

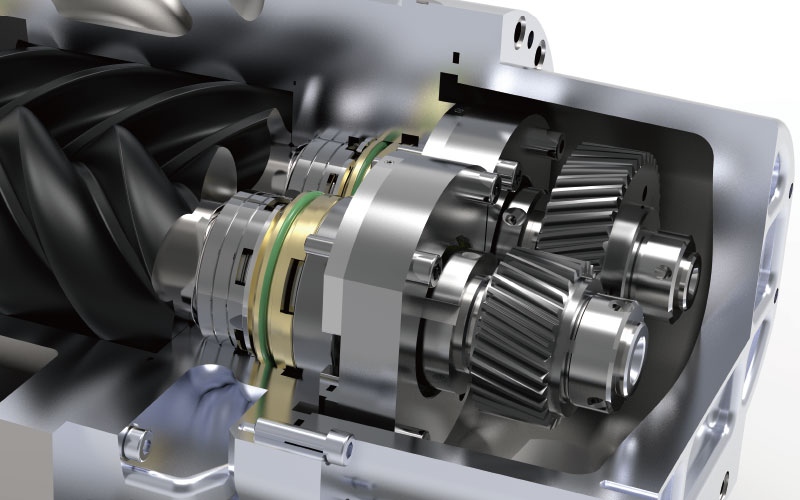

Equipped with advanced rotors, optimized structure, achieving a 12% efficiency improvement.

Smart Control

Equipped with Siemens intelligent controllers, real-time monitoring and adjusting parameters.

Reliable and Durable

Powered by Siemens zero-service coefficient motors, ensuring accurate energy data.

Quality

Our second-generation oil-free compressors prioritize quality as the core requirement.

Equipped with advanced rotors, optimized structure, achieving a 12% efficiency improvement, reducing operating costs, high air output, and low specific power.

Equipped with Siemens intelligent controllers, real-time monitoring and adjusting parameters, extending operating time, and reducing energy consumption.

Powered by Siemens zero-service coefficient motors, ensuring accurate energy data, preventing motor overload, providing you with reliable, intelligent, and energy-saving compression equipment.

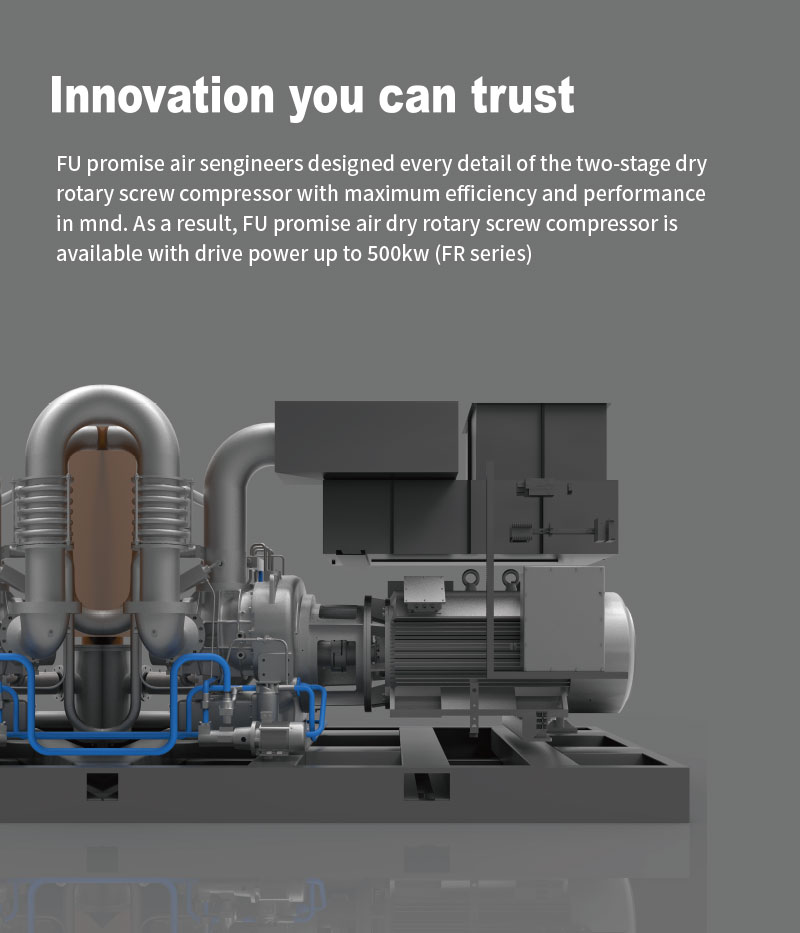

Innovation

The series compressors showcase innovation in multiple aspects.

Equipped with full original Donaldson filtration systems,

effectively reducing resistance and improving filtration efficiency, providing high-quality air sources for equipment operation.

Equipped with Siemens intelligent controllers, not only can system parameters be monitored and adjusted in real-time,

but in the event of a fault, email notifications can be sent promptly, allowing remote management and response via a web browser, achieving intelligent and convenient operation.

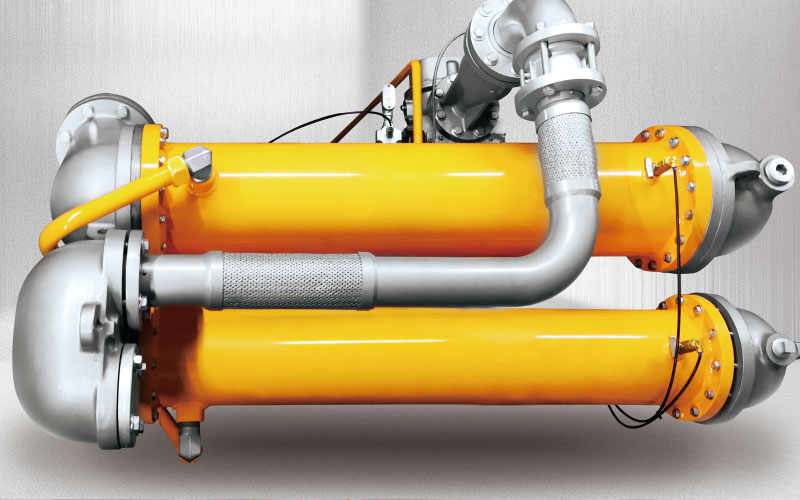

In terms of cooling performance, the fouling coefficient of the cooler can be increased by 15%, ensuring stable operation even in dusty environments,

coupled with cooling oil that has strong affinity with air, enhancing compression efficiency, allowing more compressed air to be processed per unit of cooling oil.

In terms of power, Siemens zero-service coefficient motors are selected to prevent compressor overload, effectively reducing energy costs.

The oil-gas separator adopts a unique design, with a separation speed below 2m/s, achieving excellent separation effects, extending the service life of post-treatment equipment and reducing consumables.

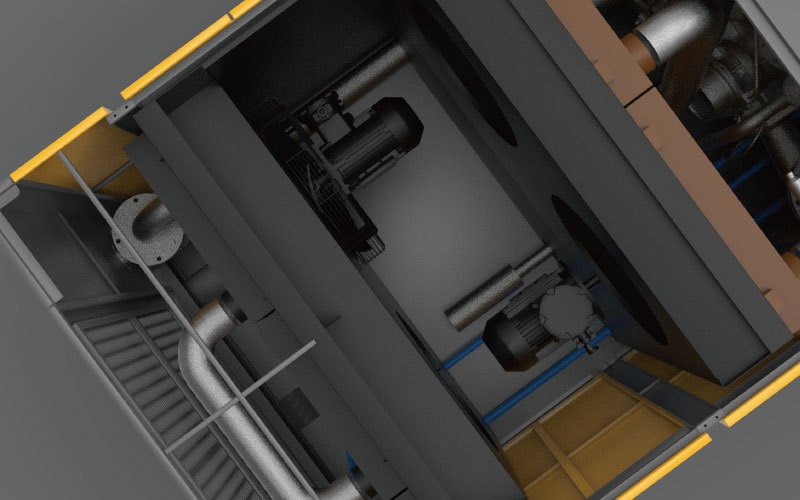

Additionally, a centrifugal negative pressure suction fan with a pressure of up to 450pa is equipped, reducing thermal interference and noise,

the compressor rotor is suitable for full-load and variable-load operation, ensuring continuous and stable gas output.

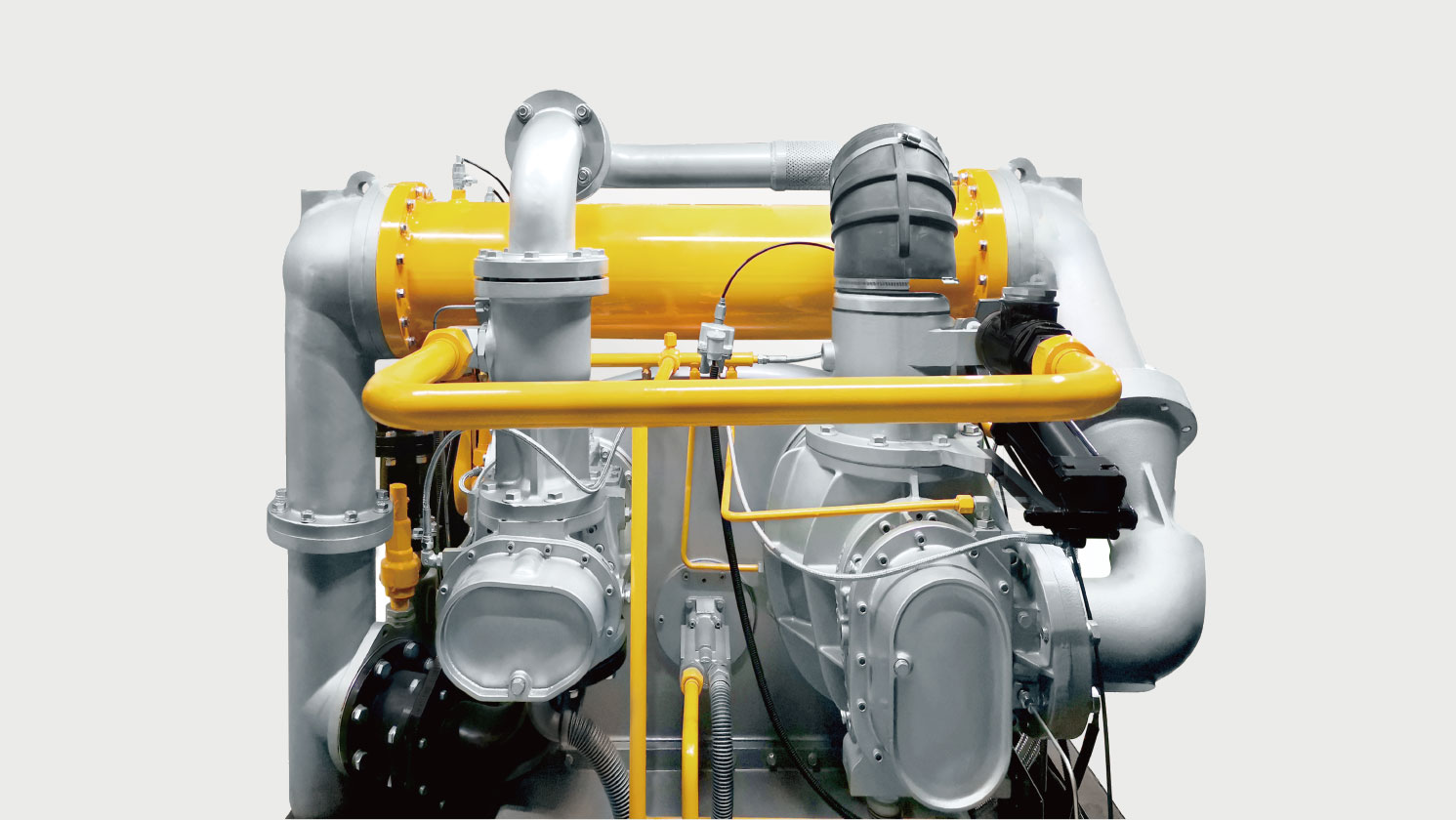

Performance

The series compressors stand out with exceptional performance.

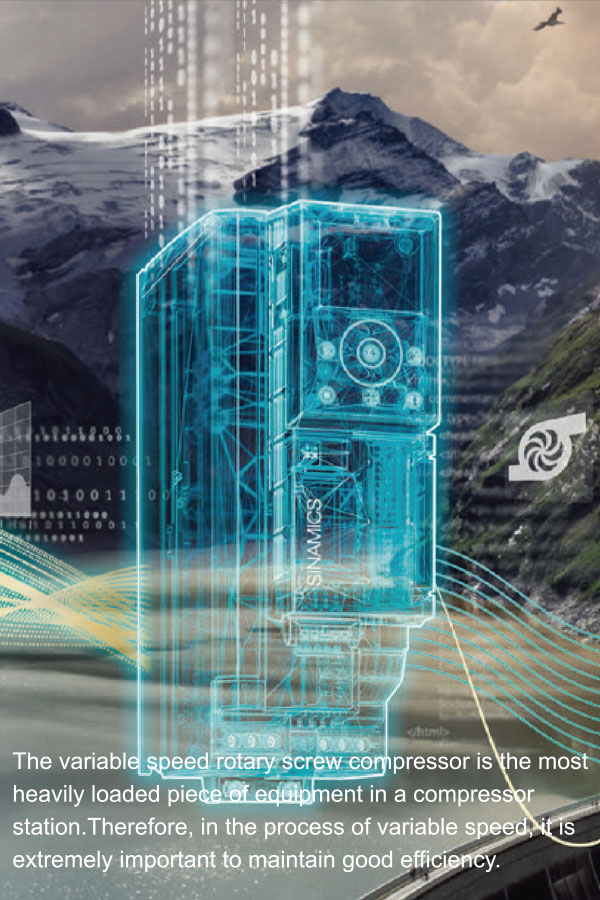

The core component, the compressor, is stable and efficient, with flow-optimized rotors ensuring continuous stable output, providing a solid foundation for equipment operation.

The Siemens intelligent PLC plays a key role, able to monitor and precisely adjust the compressor's operating state in real-time,

keeping it in an economically efficient operating mode, effectively reducing energy consumption and operational costs.

In terms of power supply, high-quality Siemens motors offer significant advantages, not only providing stable and reliable drive support for the compressor,

but their zero-service coefficient and continuous load operation capabilities also reduce maintenance needs and downtime,

demonstrating the high reliability and durability of Siemens products.

Additionally, the oil-gas separator features a unique design with a separation speed below 2m/s, achieving excellent separation effects,

extending the lifespan of post-treatment equipment and reducing consumables.

Moreover, a centrifugal negative pressure suction fan with a pressure of up to 450pa is equipped, reducing thermal interference and noise,

the compressor rotor is suitable for full-load and variable-load operation, ensuring continuous and stable gas output.

Intelligence

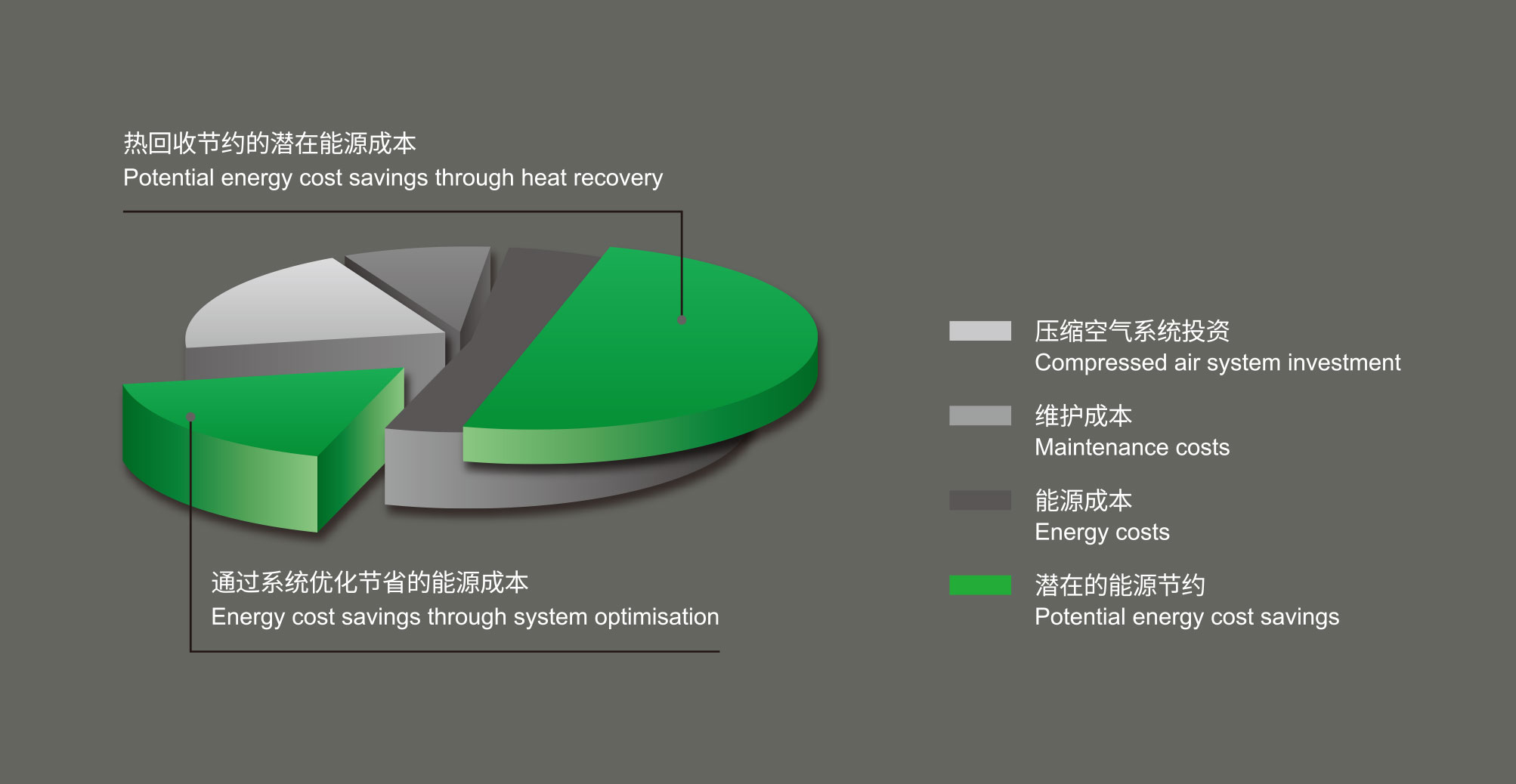

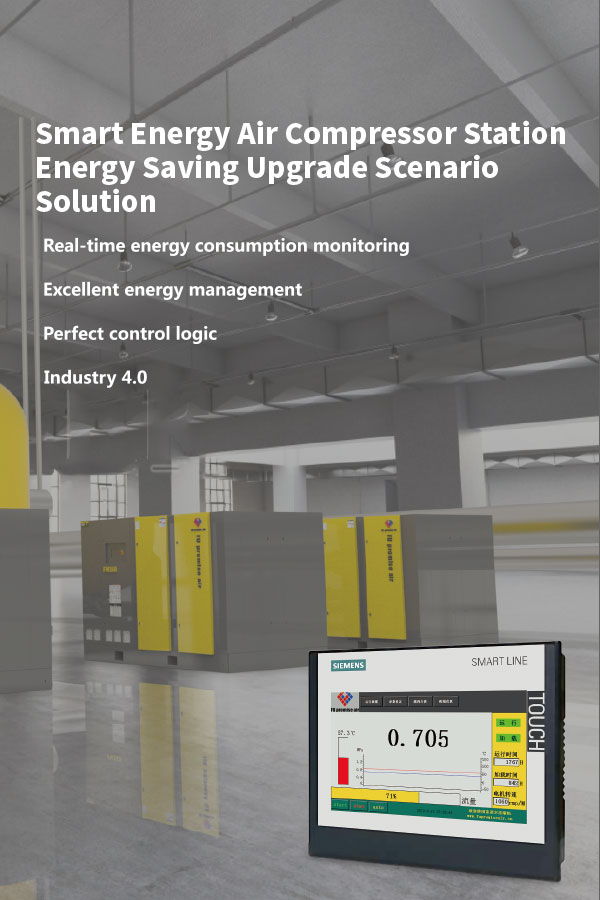

Fu promise air intelligent compressors bring smart upgrades to your industrial air stations. Breaking industry boundaries, we build an "IoT device + cloud platform + ecosystem service" system, aiding enterprises in energy efficiency improvements.

Pressure control accurate to three decimal places, tailored to production needs, saving gas costs.

Adaptable to environments ranging from -20℃ to 28.8℃ DC voltage, -20℃ to 60℃ temperature, and 90% humidity without condensation, with impact resistance up to 15g / 11ms.

Real-time energy consumption monitoring and management. Using Siemens technology, communication and data exchange are seamless. Optimizing unit operation reduces energy consumption; Siemens controllers enhance logic, precisely regulating components.

User-friendly functions, SD card for automatic program updates; Ethernet interface compatible with various devices; remote diagnostics for unit operation assurance; isolated serial port compatible with multiple brand PLCs.

Oil-Free Compressor Specifications

--Get Exclusive Solutions Immediately

Whether you need standard models for quick delivery or customized systems for complex conditions, Fu promise air's engineering team is always ready to provide professional advice.

Contact Number: +86 19822010416 / +86 18822247917

Contact Email: fcssale@fuairchina.cn

Contact Address: Tianjin Bailitai Development Zone Fu promise air Compressor Factory